We are always keen in being able to offer you the latest technical requirements.

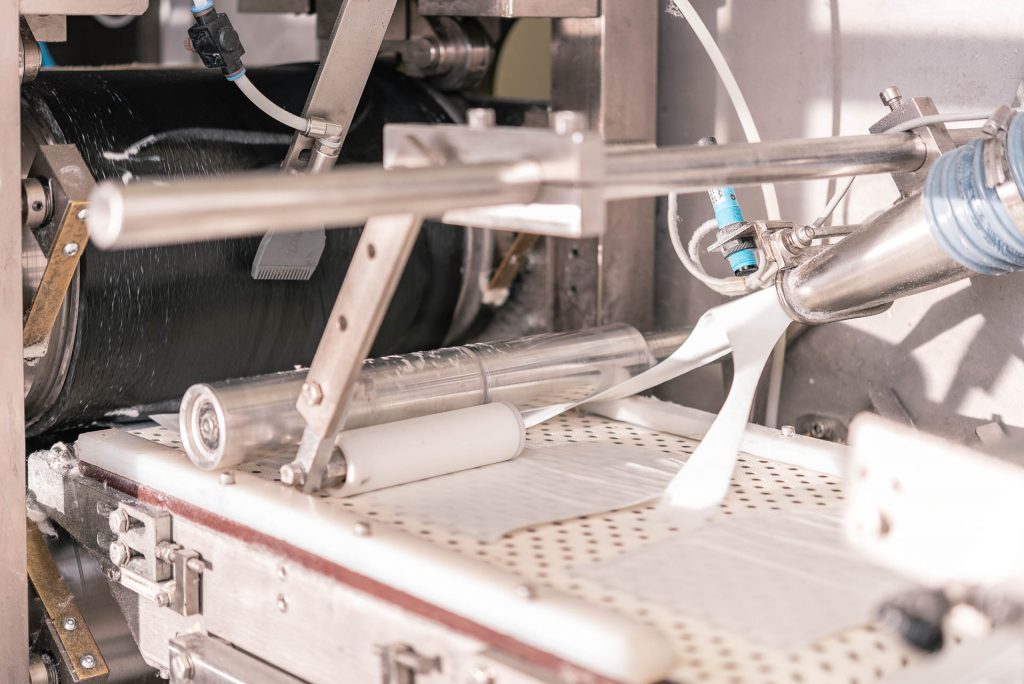

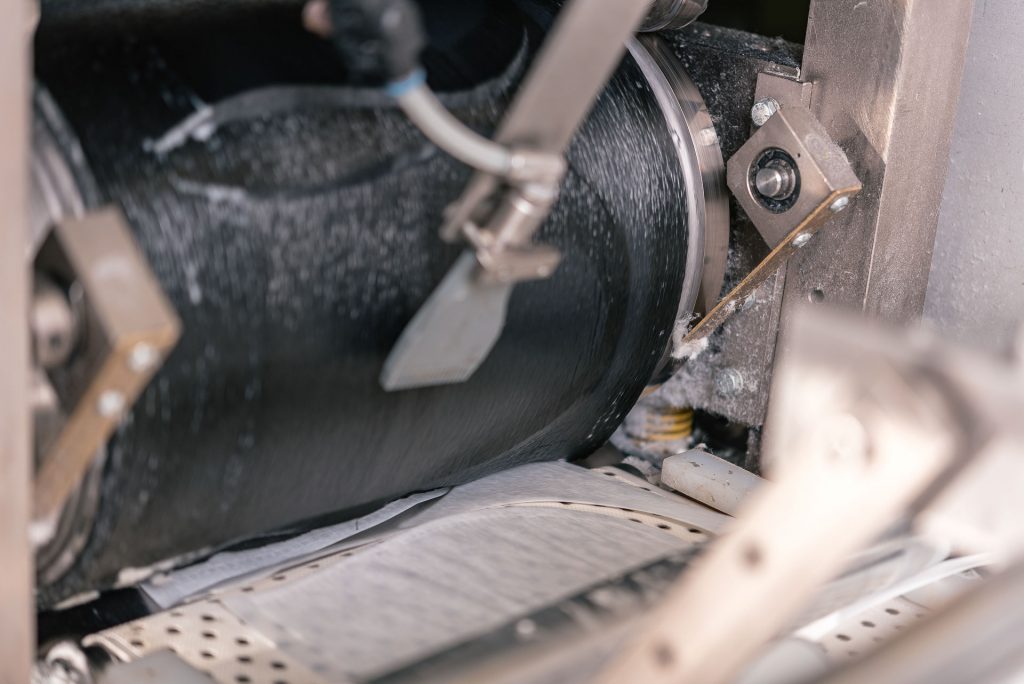

We are currently producing flowpacks, cans, rolls and buckets on ten production lines, all of which can be operated in a three-shift system, thanks to our well-trained staff.

Through constant internal and external maintenance and close cooperation with the manufacturers of our machines, we are able to offer you a flexible and ultra-modern technology park that meets your requirements for special and high-quality products.

We have an integrated quality management system and are certified according to the following standards:

DIN EN ISO 9001 : 2015

ISO 13485

ISO 22716 (cosmetic GMP)

Are you looking for a product that sets you apart from your competitors? No problem – we can also offer you a variety of product certifications.

PEFC

FSC®

An important aspect of our corporate policy is the protection of the environment and natural resources. Our employees are encouraged to work in a clean and resource-conserving manner. The pollution of the environment by chemicals is avoided and the amount of waste and reject is kept to a minimum.

The safety of the company and its products is guaranteed by various measures and facilities:

The following tissue materials are used by Innovate and can be processed for any application:

We also have special unique fabric types adapted to your customer requirements. Please contact us.

Vis = Viscose

PP = Polypropylen

For cosmetic, cleaning or disinfection products we develop and formulate the wetting lotions according to your needs. In addition, we have an ultra-modern piping system at our disposal, which offers high process reliability and reduces chemical cleaning through the use of rocking and steam. This enables us to change products quickly between different procedures. We have a chemical-physical and a microbiological laboratory at our disposal. New formulations are tested externally as standard in a preservative stress test and in a dermatological test.

Selection of raw materials:

When selecting raw materials, ecological criteria such as biodegradability, environmental and skin compatibility (Öko-Test, BDIH, etc.) are taken into account. The raw materials are used according to the application in cosmetic, food, pharmaceutical (Ph.Eur.) or also technical quality. The quality is always ordered with the highest required standard. As a downstream user, we communicate with our suppliers to ensure REACH conformity.